Apex manufactures a variety of printing systems for packaging products. Many of these applications are covered elsewhere in our industry specific pages for different manufacturing sectors and include items like cans, tubes, buckets and containers of all descriptions.

Apex manufactures a variety of printing systems for packaging products. Many of these applications are covered elsewhere in our industry specific pages for different manufacturing sectors and include items like cans, tubes, buckets and containers of all descriptions.

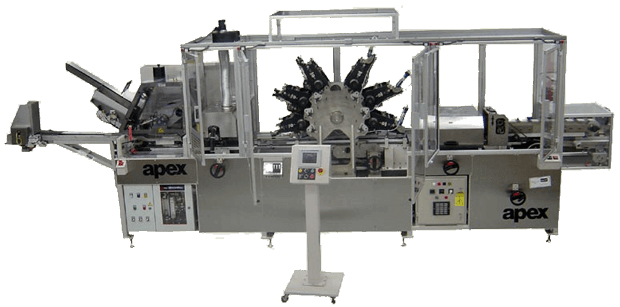

Apex also builds machinery for special packaging purposes including S-40 Machine Variants designed to handle and overprint onto pre-manufactured Folded Boxes - paper, card and corrugated - to enable marking and branding of universal bulk produced boxes with specific product detail requirements at the packaging point. For manufacturers with a wide variety of products, that can be packed into a small range of standard size boxes, these printers can provide significant savings in inventory costs for pre-printed boxes or for pre-printed label stocks and the costs involved in applying these.

Apex has a comprehensive market-leading range of printers for continuous strapping of all types. These printers set new standards of quality with their capability for imprinting high quality, close register, multi-color artworks at high speeds.

Machine types in this area include:

Strapping Printers

S-11 Strapping Printers

Introducing High Quality Print on Strapping

Apex strapping printer systems are designed to print a variety of different strapping materials of various widths to provide high quality multi-color printed images with close registration capability between colors. The Apex system can be configured in up to 4 colors, offering capability and quality solutions not previously available.

Operation

The appropriate width strapping material is webbed onto an automatic pulling unit where the controls are activated to pre-treat the material, to print it in multiple colors using the dry offset printing process, and dry the print image either by exposure to ultraviolet light, or by hot air to cure the graphics. The printers can be configured to handle from 1 to 12 lanes - thus providing the potential for high production levels where needed. The standard printing heads will provide a maximum repeat length of up to 17 inches - where longer repeats are required, a machine variety with larger print cylinders can be offered with a maximum repeat length of 27 inches.

Apex Strap Printers can be engineered to run as stand-alone off-line systems or, alternatively can be configured to run in line with a customer’s extruding in multi-lane configurations at production rates of up to 375 feet per minute per lane.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

S-40 Flat Parts Printers

S-40 Multi-Purpose Flat Product Printers

S-40 printing machines from Apex offer a wide range of options for the printing of flat surface products of all types. Any of the print technologies and methods can be incorporated into these machines which are used to print a hugely diverse range of products. The S-series machines can be engineered to handle:

- rigid self-supporting parts such as blocks, solid molded or heavy-walled products

- flexible products such as ice cream carton lids, lunch meat packs, etc., requiring support for printing

- odd shaped products which have one or more flat planes for printing, including items like cosmetic products boxes and containers, plastic paper clips, hanger clips, lids, pre-made boxes for label and details overprinting.

- products requiring printing on more than one plane like egg boxes

- sawblades, lids, cap tops, rulers, single dosage packs and many more.

All systems can be supplied with the appropriate print technologies, handling and treatment options as required. Production speeds are generally over 100 parts per minute - product size is unlimited.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.