With the ability to design and manufacture parts handling and printing lines to suit an almost infinite variety of products, Apex is the first port of call for many manufacturers of specialist hardware and general purpose products. The range covered currently includes items like Level Bubbles; Caulk Tubes; Squeeze Tubes, Circular Saw Blades, Hacksaw Blades, Handsaw Handles and Blades, Holesaw and Jigsaw blades; Flashlight (Torch) canisters; Measuring Tapes; Extruded Moldings - wood effect and other; Screw Boxes & Tubes, Tools - rigid cylindrical and flat shapes; Yardsticks and Rules.

Machines in these product areas include:

S-40 Flat Parts Printers

S-40 Multi-Purpose Flat Product Printers

S-40 printing machines from Apex offer a wide range of options for the printing of flat surface products of all types. Any of the print technologies and methods can be incorporated into these machines which are used to print a hugely diverse range of products. The S-series machines can be engineered to handle:

- rigid self-supporting parts such as blocks, solid molded or heavy-walled products

- flexible products such as ice cream carton lids, lunch meat packs, etc., requiring support for printing

- odd shaped products which have one or more flat planes for printing, including items like cosmetic products boxes and containers, plastic paper clips, hanger clips, lids, pre-made boxes for label and details overprinting.

- products requiring printing on more than one plane like egg boxes

- sawblades, lids, cap tops, rulers, single dosage packs and many more.

All systems can be supplied with the appropriate print technologies, handling and treatment options as required. Production speeds are generally over 100 parts per minute - product size is unlimited.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

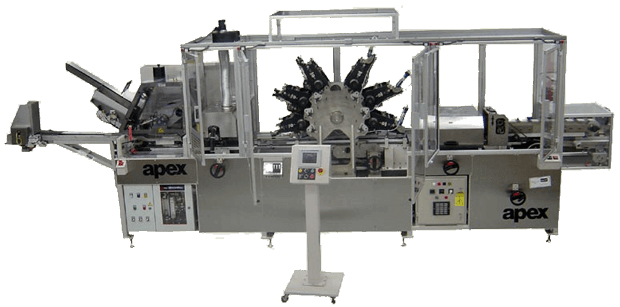

S-40 Hacksaw Blade Printers

S-40 Hacksaw Blade Printers

S-series printing machines from Apex offer a wide range of options for the printing of flat surface products of all types. Any of the print technologies and methods can be incorporated into these machines which are used to print a hugely diverse range of products. In the example below the machine has been configured specifically for printing onto sawblades with automated feeding, printing, drying and integrated counting, bundling and taping at the delivery end of the machine.

The S-40 Saw printer range includes versions to handle circular saw and other types of blades requiring brand printing, barcoding and/or coating.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

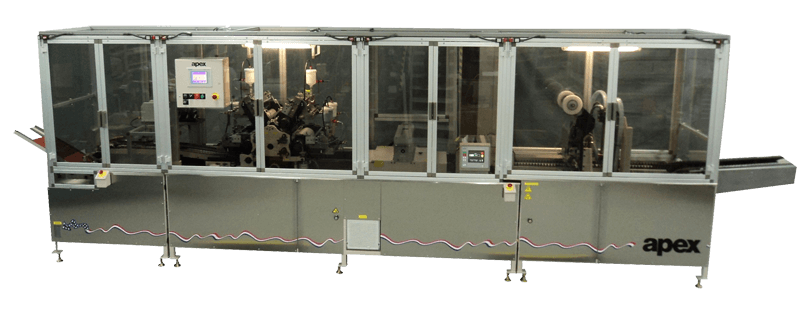

C-506 Cauk Tube Printers

C-506 Cylindrical Parts Printers

A 6 color system designed to enhance the aesthetic value of your product - discover the world of unparalleled print quality.

The C-506 utilizes mandrels to support flexible or rigid parts to allow printing on their full length, and 360 degrees around. Parts commonly printed on the C-506 include:

The C-506 utilizes mandrels to support flexible or rigid parts to allow printing on their full length, and 360 degrees around. Parts commonly printed on the C-506 include:

• Cans • Bottles • Cartridges • Containers • Cups • Tubes

Whether you are looking for high quality printing on metal or plastic; cups, cans, containers or tubes, the Apex C-506 consistently delivers the solution. Capable of printing both rigid and flexible cylindrical parts with a copy length of up to 12 inches.

The C-506 can incorporate a range of feeders, pre-treaters, cleaning systems, decoration units, dryers, coaters and unloading systems. Moreover, the system can also integrate automatic capping stations, side seam detectors as well as our revolutionary and recently developed Quick Change features.

Interfaced within are the appropriate:

Feeder / Loader

The feeding of your components to the system can be simple or sophisticated, depending on your specific production requirements. Typically, hoppers and bowl feeds are utilized for smaller components whereas inline conveyors and chutes are used for larger parts.

Pre-Treaters

Gas treaters or corona discharge units are most often used to pre-treat parts to remove any excess lubricants or contaminants that might hinder the highest print quality and adhesion. Additional cleaning options include de-ionized air jet systems as well as static eliminators to assist in superior lay down of ink. Any of these cleaning systems can be integrated in the C-506 and each is available in a variety of formats to suit each customer’s unique requirements.

Decoration Unit

Any decoration technology can be integrated in the C-506. For multi-color applications, we recommend either dry offset print, which can be supplied in different widths with up to six color printing heads or, where high density colors are required, our FlexApex system can be used either on its own or in combination with dry offset. For overcoating applications, we suggest rotary silk screening, rotary hot stamping, letterflex or flexographic printing, with each type specifically designed and interfaced to suit your requirements.

Dryers

Forced hot air, infrared, convection and ultraviolet curing styles of drying can be supplied to cure the appropriate ink for each customer’s specific needs.

Quick Change Features

Apex has developed industry revolutionizing technology that allows for a 6 color ink and plate change in just minutes, thereby nearly eliminating downtime. With the market trend moving towards shorter and shorter runs of production, this optional feature has proved to be decisive in justifying ROI’s for our clients, many of whom have been experiencing huge downtimes.

As with all Apex machines, we tailor each one to suit the individual customer's specification and requirements.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

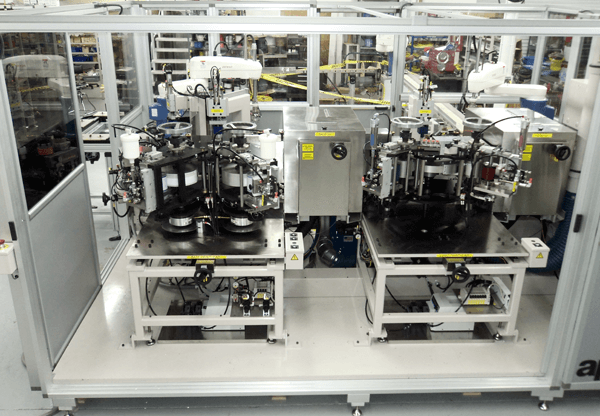

C-40 Tubular Products Printers

C-40 Cylindrical Parts Printers

Apex C-40 series printers are highly adaptable to suit a wide variety of specialist printing and decorating applications. The flexible design characteristics enable the machines to have considerable scope for size adjustments to allow a variety of products to be printed. The C-40 can be supplied with a variety of print technologies ranging from dry offset and gravure, to hot foil applications or specialist coatings.

Diverse applications for the C-40 range include:

Diverse applications for the C-40 range include:

Lipstick Tubes, Golf Balls, Cans, Rigid Tubes, Corks, Cups, Bottles, Squeeze Tubes, Pill Jars and Glue Sticks to name just a few.

The C-40 can be supplied as a complete semi-automatic straight wall cylindrical part printing system that includes a feed station, pre-treat station, print station, UV drying station, and optional eject station all in one small footprint.

This machine is designed so that parts can be manually loaded onto mandrels located on a four or eight station rotary index wheel. On a four mandrel index wheel, the load mandrel is also the exit mandrel. An optional automatic eject can be added to the eight mandrel system. The C-40 can also be supplied with part or full automation for higher speed operation.

Following the loading section is an optional Gas Flame or Corona pre-treatment section where the part is rotated and the circumference is pre-treated prior to its entrance into the print station. Following the pre-treatment is the print section, where colors and graphics are added to the part. Next, the part indexes into a UV curing section where the part is rotated and the circumference is exposed to the UV light source until the ink is "cured" and dry. Finally, the part indexes so that it can be ejected.

Either a mechanical part holder or an optional Vacuum Assist mechanism is typically utilized to secure the part to a mandrel. An optional Rotational Orientation Device can be integrated on each mandrel to register the imprint on the part.

For multiple color capacity, this machine utilizes either Dry Offset or FlexApex printing methods for decorating the cylindrical objects. Each Dry Offset Print Head includes a 360° plate drum allowing for the use of Photopolymer Print Plates. These plates may be secured using a variety of optional plate mounting systems, for example, Vacuum, Magnetic, Strap-On or Double Sided Tape.

The print station can consist of up to Four Dry Offset Heads printing circumferentially on the part. If the part incorporates STRAIGHT WALLS, a 360° artwork wrap can be achieved. An optional angling device can allow for tapered parts to be printed however, the more the taper, the less artwork wrap can be achieved. In either case, spot artwork can be printed around the circumference.

The C-40 in manual loading mode operates at about 20 to 35 parts per minute, limited only by the speed of the operator. It is ideally suited for a wide variety of cylindrical products including cups and tubes. In automatic loading configurations higher operation speeds of up to 100 parts per minute can be achieved.

The following is a listing of standard options:

- Four or Eight Station layout

- Orientation Device

- Vacuum Part Assist

- Mechanical Part Assist

- Gas Flame Treating Station - for 3", 6" or 9" wide print area

- Corona Treating Station - for 3", 6" or 9" wide print area

- Up to Four Dry Offset Print Heads - for 3", 6" or 9" wide print area

- Vacuum, Magnetic, Strap-on or Double-sided Tape plate mount systems

- Ultraviolet Light Drying System - for 3", 6" or 9" wide print area

- Air Blow Off or Mechanical Eject System

- Choice of Printing Systems - Dry Offset, Flexapex, Hot Foil

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

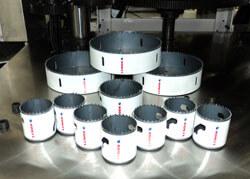

Holesaw Printers

Custom Built Holesaw Printer

Apex Machine will build special application machinery to meet specific client requirements. Pictured below is a custom designed production line for coating and printing a wide variety of sizes of holesaws. For special applications please contact us.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.