Custom engineering and manufacturing of specialist machinery and turn-key solutions for the medical and pharmaceutical industry sectors is an area where Apex has a track record of success at the leading edge of development. Our ability to provide solutions for critical components where accuracy, repeatability, and quality are paramount has placed Apex as a first choice supplier for many household names in the industry for many years.

We routinely provide turn-key systems in this market area, working together with major suppliers in the fields of plastic injection moulding, complex parts assembly systems, vision systems and others as appropriate to provide the ideal solutions for our customers. We have a dedicated department providing IQ, PQ and OQ support for our customers so we are able to interface and assist with project developments at all stages. Typically our involvement with projects may commence at the planning and design stages, where we are often able to provide input regarding suitability of parts for handling and printing. We regularly conduct trials for customers to assess the suitability of parts and materials for compliance with the printing, marking or decoration methods that may be envisaged.

Our corporate aim is to work with customers in this industry area as long-term partners, acting not only as a machinery solutions provider but also as a development arm to assist with projects where our expertise is relevant.

The product sectors for which we currently supply systems include:

Catheters & Stents

Catheters, Stents and Tubing

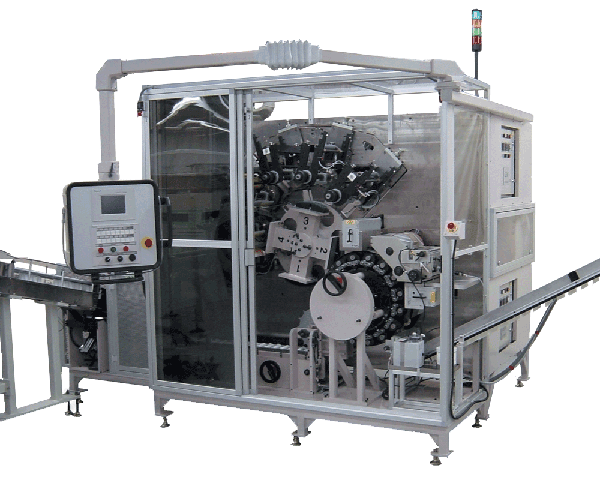

Apex C25 Catheter & Stent Printers

Apex C25 Catheter & Stent Printers

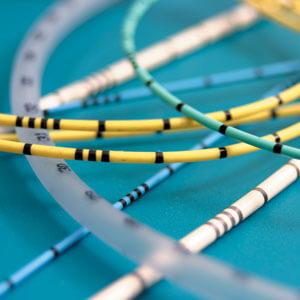

The C-25 is primarily designed for catheters and stents, automatically capturing, printing, curing and exiting a multitude of pre-cut product lengths and diameters at production speeds of up to 40 parts per minute.

The C-25 can be supplied with rotary gravure, dry-offset and/or FlexApex print heads in many combinations, to print a range of graphics that include both text, graduation lines, and calibration marks on the full length of the tube, 360° around. The C-25 can also utilize FDA inks to offer a VOC-free system, safe and suitable for most medical applications.

The C-25 can be supplied with rotary gravure, dry-offset and/or FlexApex print heads in many combinations, to print a range of graphics that include both text, graduation lines, and calibration marks on the full length of the tube, 360° around. The C-25 can also utilize FDA inks to offer a VOC-free system, safe and suitable for most medical applications.

Apex also offer solutions for continuous printing onto extruded tubes in single or multi-lane configurations. Please ask us for details.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Cryule Vials & Desiccants

Cryule Vials & Dessicant Cannisters

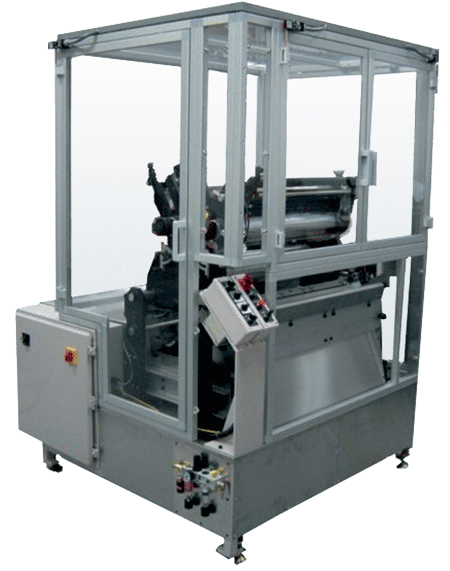

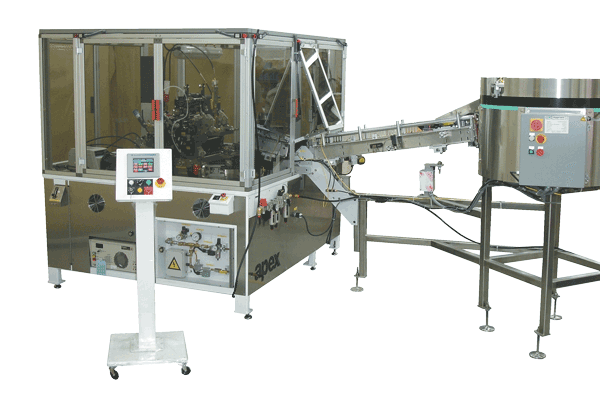

Apex C-400 Cryule Vial Printer

Apex C-400 Cryule Vial Printer

The C-400 cryule vial printer implements an index-motion or continuous-motion alligator transport chain to automatically capture cryule vials or other round, cylindrical medical components from a feeding station. These are carried in the transport chain through pre-treat, print, cure and capping stations before exiting into a receiving container.

The system is designed for rigid cylindrical components with production speeds of up to 250 parts per minute.

The system is designed for rigid cylindrical components with production speeds of up to 250 parts per minute.

This system can also be supplied with unique feeding, treating and printing systems, curing stations, and automation at the exit end to offer a fully-automated, turnkey solution, operating inline or offline with the client’s molding and packaging equipment.

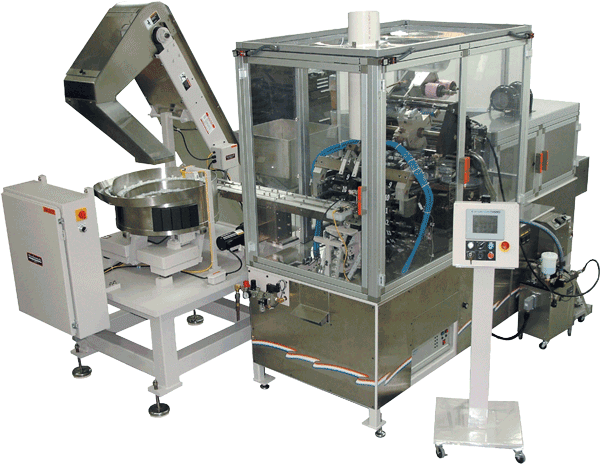

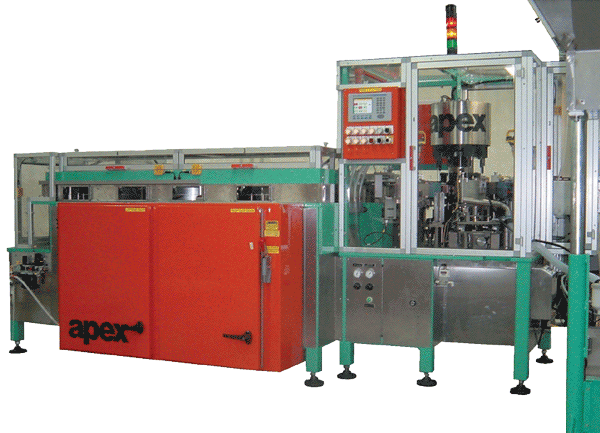

C-40 Dessicant Cannister & Cryule Vial Printers

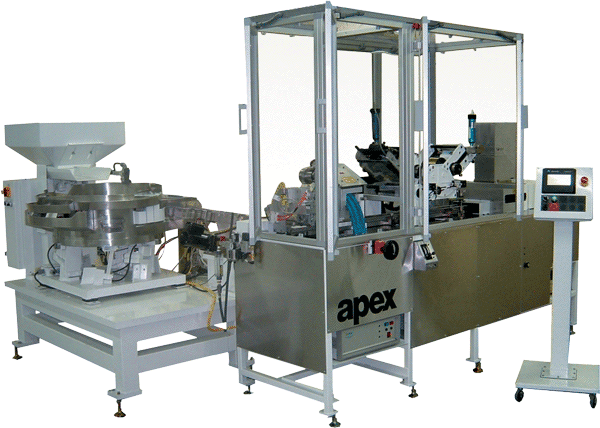

The C-40 is normally supplied as a fully automatic system with desiccant canisters or cryule vials being fed, manually or automatically, into an appropriate bulk bin. Once accumulated in the bin, the vials or canisters are then automatically fed into the orientating and singulating system. From there the product will be automatically treated, printed, cured and capped prior to ejection into a bag, part accumulation bin, or automatic packaging system.

The C-40 is normally supplied as a fully automatic system with desiccant canisters or cryule vials being fed, manually or automatically, into an appropriate bulk bin. Once accumulated in the bin, the vials or canisters are then automatically fed into the orientating and singulating system. From there the product will be automatically treated, printed, cured and capped prior to ejection into a bag, part accumulation bin, or automatic packaging system.

This range of printers is used across a wide range of industry sectors and the various models can be configured to accept many types of small rigid tubular shaped items ranging from corks to lollipop sticks.

This range of printers is used across a wide range of industry sectors and the various models can be configured to accept many types of small rigid tubular shaped items ranging from corks to lollipop sticks.

A wide choice of printing systems, pre-treatments and speeds are available.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Dental Needles

Needle Cartridges

Apex S-40 Needle Cartridge Printer & Coater

Apex S-40 Needle Cartridge Printer & Coater

The S-40 style machine is typically supplied for printing 1-side of flat surface parts, however the basic system can easily be adapted and configured to handle printing onto multiple surfaces and sides. The pictured machine was designed to orientiate, feed, capture, coat the tops, dry, coat the taper (circumferentially), dry, inspect, exit, and accumulate predetermined quantities of dental needles into plastic boxes at a speed of approximately 100 parts per minute.

The S-40 Apex Printing system utilizes a building block, modular machine concept, allowing this system to be equipped with multiple and varied feeding and pre-treating systems, different printing technologies, printing stations, coating stations and curing stations. Vision inspection systems and a variety of part packaging systems can also be incorporated.

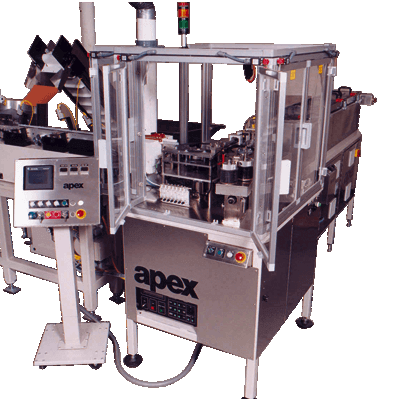

Apex C-40 High Speed Needle Cartridge Printers

The C-40 will automatically feed, treat, print, dry, and exit needle cartridges of various lengths. Bulk cartridges are automatically or manually loaded into a bulk bin, which presents the cartridges into the feeder in predetermined quantities. The feeder will orientate the cartridges and present them into the Apex machine via a vibratory track and with constant back pressure.

The C-40 will automatically feed, treat, print, dry, and exit needle cartridges of various lengths. Bulk cartridges are automatically or manually loaded into a bulk bin, which presents the cartridges into the feeder in predetermined quantities. The feeder will orientate the cartridges and present them into the Apex machine via a vibratory track and with constant back pressure.

Prior to the cartridge’s entrance into the print station, the printable area of the cartridge is corona pre-treated to ensure high quality print adhesion characteristics. A rotary dial is used to escape the treated parts from the vibratory track and present them into the print station.

Prior to the cartridge’s entrance into the print station, the printable area of the cartridge is corona pre-treated to ensure high quality print adhesion characteristics. A rotary dial is used to escape the treated parts from the vibratory track and present them into the print station.

In the print station the graphics are printed using the dry offset printing process and presented into an ultraviolet dryer where the ink on the cartridge is cured before it is ejected out of the machine into a receiving container, or part packaging system. The complete system has an approximate production rate of 250 to 300 parts per minute, with the actual speed being dictated by the size, consistency and the quality of the parts.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Medical Tubes

Medical Tubes

Apex makes a variety of machines for printing onto all types of medical tubes, offering a range of speed, color and handling capabilities to suit almost every requirement.

Apex C-500 Tube Printer

Apex C-500 Tube Printer

The C-500 is shown is tooled for medical tubes, and will automatically feed, treat, print, cure, inspect and exit medical tubes at production speeds of up to 150 tubes per minute. Many styles of cylindrical medical components requiring internal support can be handled on the C-500.

Custom modules and features can also be applied within this system to offer a fully-automatic, turnkey system, featuring extreme versatility and user-friendly operation.

Custom modules and features can also be applied within this system to offer a fully-automatic, turnkey system, featuring extreme versatility and user-friendly operation.

Customized vision systems can also be integrated into the C-500’s modular design, assuring print quality and part integrity prior to either ejecting or accumulating parts at the exit end.

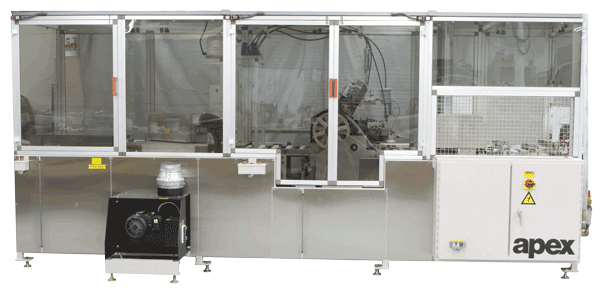

Apex C-90 Centrifuge Tube Printer

Apex C-90 Centrifuge Tube Printer

The C-90 is designed for centrifuge tubes and can handle both 15ml and 50ml polystyrene or polypropylene tubes at production speeds up to 500 parts per minute.

The C-90 is normally supplied in a fully-automated configuration accepting centrifuge tubes in bulk, capturing, orientating, feeding, pre-treating, printing, curing, capping, ejecting and bagging/boxing or simply accumulating product automatically. Customized vision systems can also be integrated into the C-90, assuring print quality and part integrity prior to either ejecting or accumulating parts at the exit end.

The C-90 is normally supplied in a fully-automated configuration accepting centrifuge tubes in bulk, capturing, orientating, feeding, pre-treating, printing, curing, capping, ejecting and bagging/boxing or simply accumulating product automatically. Customized vision systems can also be integrated into the C-90, assuring print quality and part integrity prior to either ejecting or accumulating parts at the exit end.

With our fully-automated exit-end options, this system can offer a turnkey solution capable of printing very high quality one or two color imprints onto medical centrifuge tubes, all virtually hands-free.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Pill Containers

Pill Containers

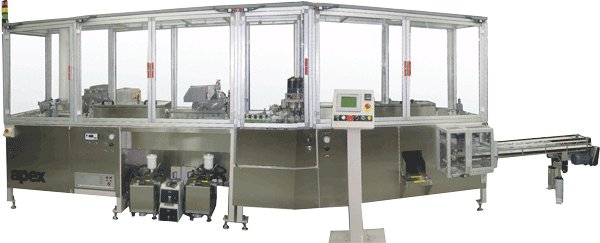

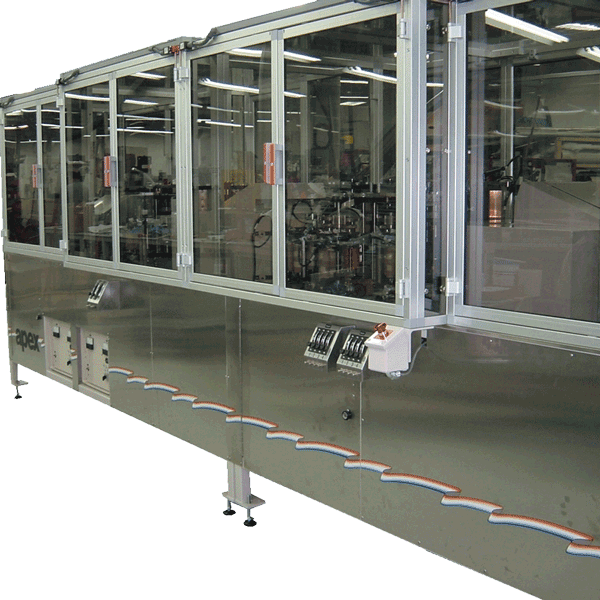

Apex C-506 Pill Container Printers

Apex C-506 Pill Container Printers

The C-506 system can be supplied either as a mandrelized machine or with chuck-support systems, so can be configured to automatically handle different types of pill containers, including those with integrated caps, at production speeds of up to 200 parts per minute.

The containers are fed into the machine in bulk, where they are captured, treated, orientated, printed in up to 6 colors, cured, optionally clear-coated and cured again, then exited into an automated packaging or part accumulation system.

The containers are fed into the machine in bulk, where they are captured, treated, orientated, printed in up to 6 colors, cured, optionally clear-coated and cured again, then exited into an automated packaging or part accumulation system.

A variety of automated print technologies, such as dry-offset and FlexApex, can be incorporated to offer the highest quality of decoration.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Pill Boxes, Security Caps

Security Caps

Apex S-40 Security Cap Printers

The S-40 range of printers can be configured to handle and print a very wide variety of flat-surface products including lids, caps and closures of all sizes, as well as for surface and/or tip printing onto raised braille or other characters on pill containers and the like.

The S-40 range of printers can be configured to handle and print a very wide variety of flat-surface products including lids, caps and closures of all sizes, as well as for surface and/or tip printing onto raised braille or other characters on pill containers and the like.

As a cap printer the S-40 can be configured for single or multi-lane feeding and for a wide range of diameters, providing solutions for both low and high volume production requirements.

The S-40 range can be supplied as stand-alone systems with semi or fully automatic feeding, or as fully in-line systems to suit particular production needs. Single or multi-face printing can be accomodated in 1 to 6 colors to provide the capability to print on sides and tops of containers in a single handling. Depending upon product type, size, number of lanes, etc., production speeds ranging from 100 to 2000 pieces per minute, or more, can be achieved.

The S-40 range can be supplied as stand-alone systems with semi or fully automatic feeding, or as fully in-line systems to suit particular production needs. Single or multi-face printing can be accomodated in 1 to 6 colors to provide the capability to print on sides and tops of containers in a single handling. Depending upon product type, size, number of lanes, etc., production speeds ranging from 100 to 2000 pieces per minute, or more, can be achieved.

Variants of the S-40 range can be supplied for printing:

- Caps and Closures of all sizes

- Medical Bags

- Pill Boxes

- Lids of all types

- Flat surface Dials and Components

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Pipettes

Pipettes

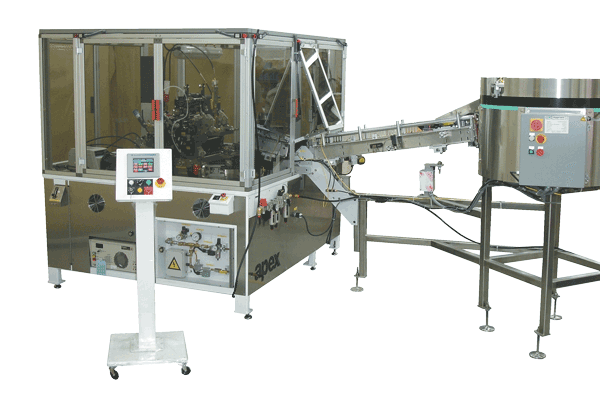

C-400P Pipette Printer

The Apex C-400-P is specifically designed for pipettes to automatically feed, treat, print, cure and exit parts into a receiving bin, with production speeds of up to 200 parts per minute.

The Apex C-400-P is specifically designed for pipettes to automatically feed, treat, print, cure and exit parts into a receiving bin, with production speeds of up to 200 parts per minute.

Up to five colors can be printed on the pipettes, with 360º of copy coverage. Dry-offset, as well as flexographic-offset heads, can be installed in any combination for greater ink coverage and extreme detail of graduation lines and text.

The C-400-P can feed and print various styles and sizes of pipettes, taking advantage of automation processes at the front or back-end to offer a fully-automated turnkey system.

The C-400-P can feed and print various styles and sizes of pipettes, taking advantage of automation processes at the front or back-end to offer a fully-automated turnkey system.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Single Dosage Tubes

Single Dosage Tubes

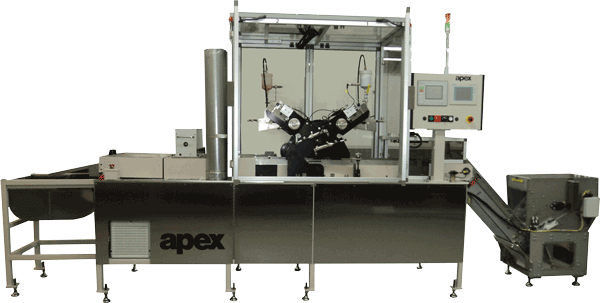

Apex S-40 Single Dosage Tube Printer

Apex S-40 Single Dosage Tube Printer

The S-40 style machine is typically supplied for printing 1-side of flat surface parts, however the basic system can easily be adapted and configured to handle printing onto multiple surfaces and sides. Pictured here is a 2-sided, fully automated system, capable of feeding, treating, printing 4 colors on both sides, curing and exiting strips of single-dosage tubes at production speeds of up to 600 parts per minute.

This unique and very versatile system, when supplied as a 1-sided machine, can readily be configured to automatically handle and print IV bags and many other flat medical components, running production speeds of up to 60 parts per minute.

This unique and very versatile system, when supplied as a 1-sided machine, can readily be configured to automatically handle and print IV bags and many other flat medical components, running production speeds of up to 60 parts per minute.

The S-40 APEX Printing system utilizes a building block, modular machine concept, allowing this system to be equipped with multiple and varied feeding and pre-treating systems, printing and curing stations, and part packaging systems.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

Syringes

Syringe Printers

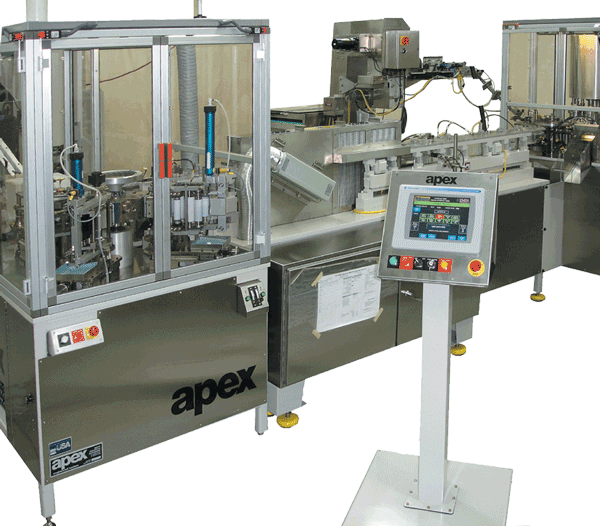

Apex C-40 Syringe Printers

Apex C-40 Syringe Printers

The C-40 is our least expensive part handling and printing system and it is specifically designed for semi-automatic applications where a low volume, versatile machine is required.This machine can be supplied for manual feeding, or with various types of automation to feed, treat, print, cure and eject a variety of medical components at production speeds of up to 60 parts per minute.

By using proven Apex components and a building block concept, the C-40 can be supplied with pre-treating systems which include both corona spot-treat or flame treat. A variety of print technologies can also be integrated within this machine. In addition to being able to offer up to 4 colors in the dry-offset configuration, this machine can also be supplied as a 1-color rotary gravure printer, 1-color rotary hot-stamper, up to 4 colors FlexApex, or a combination dry-offset and FlexApex printing machine.

A variety of different curing units can be incorporated to offer either infrared, convection, or ultraviolet curing applicable for the client’s appropriate inks and product requirements. Medical devices of varying styles and sizes can be printed on this machine, but the C-40 typically handles parts less than 155mm in diameter and 300mm in length.

Apex C-500 Syringe Printers

The C-500 is an index-motion part handling system, supplied with servo-driven 8-station, 12-station or 16-station horizontal dials to suit a wide variety of medical devices and customer requirements.

The C-500 is an index-motion part handling system, supplied with servo-driven 8-station, 12-station or 16-station horizontal dials to suit a wide variety of medical devices and customer requirements.

The C-500 is also of a modular design and, as with other Apex machines, utilizes a building block concept to integrate various features suitable for each application within the system. Extensive and varied feeding systems can be integrated within the C-500 to accept parts in bulk and to sort, orientate and feed these into the machine in a fully automated operation. Often this is done in-line with the client’s molding machines. These feeding systems include rotary, vibratory, centrifuge and hopper feeders, in-feed conveyors, vertical chutes and linear conveyors with servo-driven part loading systems. Pre-treatment units can also be integrated to pre-treat components with flame or corona discharge units.

The Apex C-500 can also be offered with different print technologies to suit specific applications with a choice from rotary gravure, 5-color dry-offset, 5-color FlexApex, hot foil stamping and as a combination system that utilizes multiple printing technologies in a customized format.

Apex C-90 Syringe Printers

The C-90 is the “work-horse” among our multiple styles of syringe printing machines. This particular machine routinely runs 24/7, at production speeds of up to 250 parts per minute.

The C-90, typically supplied as a fully automated system, accepts a variety of styles and sizes of syringes in bulk and will automatically capture, singulate, orientate, treat, print, cure and exit parts utilizing many technologies. As with most Apex machines, the C-90 can also be fully customized to suit each customer’s exact needs and requirements.

Options include feeders, pre-treatment, orientation (flange and zero-line), print, cure, vision/inspection, auto-reject, auto-eject, assembly functions, part accumulation, and auto-carton/auto-boxing.

Apex C-900 Syringe Printers

The C-900 is the fastest disposable syringe printing machine in the world.

This system can be supplied with or without mandrels, to automatically feed, treat, orientate, print, cure and exit a range of different disposable syringes at production speeds of up to 800 parts per minute.

The C-900 can be supplied with a variety of feeding, pre-treating and orientation systems, curing units, vision inspection systems, part accumulation and packaging modules to suit each customer's needs and requirements.

For high-speed disposable syringe printing applications, the C-900 is clearly the industry leader. Approximately 250 of this machine type are in production, on a 24/7 basis, with the top syringe manufacturers in the world.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

In addition we make a wide range of custom machines for components of all sorts, dials, barrels, etc, for insulin and other medical devices. Please contact us to discuss your specific requirements.

To contact our medical/pharma team to arrange to discuss your project, please email a short description of the project and your contact details to: