Apex offer a number of different printing systems for food industy related product types. These include Flat Sticks and Scoops for Ice Creams & Lollies; Cups; Meat Packs; Tubes and Containers; Chop Sticks; Ice Cream Cartons and Lids; Margarine Containers; Yogurt Cups & Lids; Clamshell type packs for Fruit and Bakery products; Egg Carton Printers; Wooden, Plastic and Paper Sticks for confectionery. Our systems are custom engineered to handle and print all shapes and sizes of products - if you have something new requiring decoration please contact us to discuss the possibilities.

Machine types in this area include:

S-40 Lid Printers

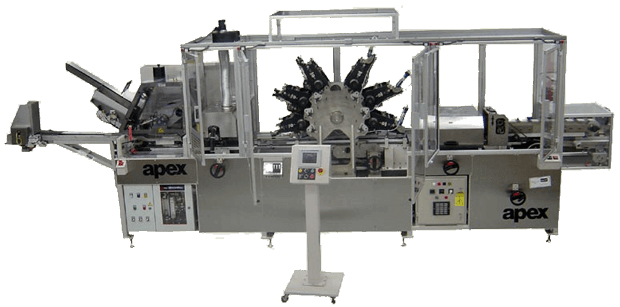

S-40 Printer for Food Packaging Lids

This derivation of the well proven Apex S-40 type machine has been specifically designed for printing onto the tops of food container lids. The machine is available to handle a variety of sizes, depending on customer requirements.

The operation involves the operator loading stacks of orientated lids into an infeed automatic scroll assembly. The scroll assembly will release the bottom lid from the stack and place it in between the set guide rails of our S-40 style base assembly.

A linear, continuous motion dual chain assembly with pushers at proper centers will come from behind the lid and carry it throughout the remainder of the machine. The first station the part will enter is a treating station where the surface will be pre-treated using an Apex flame treating system for proper print and adhesion quality.

Following the flame treating station is a 6-color dry offset print station. The next station is an Apex UV dryer to cure the ink before the lids exit out of the system and into an automatic re-stacker system. The complete system has an approximate production rate of 100 parts per minute.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

S-40 Flat Parts Printers

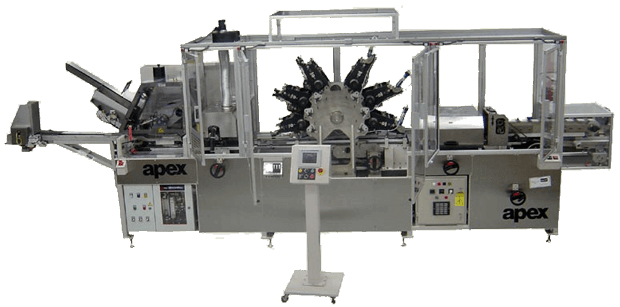

S-40 Multi-Purpose Flat Product Printers

S-40 printing machines from Apex offer a wide range of options for the printing of flat surface products of all types. Any of the print technologies and methods can be incorporated into these machines which are used to print a hugely diverse range of products. The S-series machines can be engineered to handle:

- rigid self-supporting parts such as blocks, solid molded or heavy-walled products

- flexible products such as ice cream carton lids, lunch meat packs, etc., requiring support for printing

- odd shaped products which have one or more flat planes for printing, including items like cosmetic products boxes and containers, plastic paper clips, hanger clips, lids, pre-made boxes for label and details overprinting.

- products requiring printing on more than one plane like egg boxes

- sawblades, lids, cap tops, rulers, single dosage packs and many more.

All systems can be supplied with the appropriate print technologies, handling and treatment options as required. Production speeds are generally over 100 parts per minute - product size is unlimited.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

C-40 Stick Printers

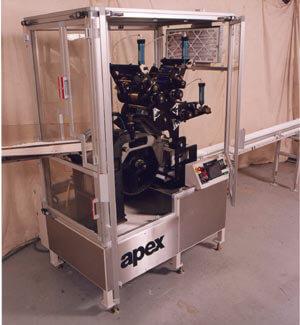

C-40 High Speed Stick Printer

Apex C-40 series stick printers are adaptable to suit a wide variety of specialist printing and decorating applications. The flexible design characteristics enable the machines to have scope for size adjustments to allow a variety of product diameters and lengths to be printed. The C-40 can be supplied with a variety of print technologies ranging from dry offset and gravure, to hot foil applications or specialist coatings.

The C-40 is a complete semi-automatic printing system that includes a feed station, pre-treat station (if required), print station, UV drying station, and eject station all in one small footprint.

The C-40 is a complete semi-automatic printing system that includes a feed station, pre-treat station (if required), print station, UV drying station, and eject station all in one small footprint.

This machine is designed for parts to be manually loaded into a hopper from where the sticks are singulated and fed into the transport dial. Following the loading section is an optional Gas Flame or Corona pre-treatment section (for plastic sticks) where the part is rotated and the circumference is pre-treated prior to its entrance into the print station. Following the pre-treatment is the print section, where colors and graphics are added to the part. Next, the part moves into a UV curing section where the part is rotated and the circumference is exposed to the UV light source until the ink is "cured" and dry. Finally, the part is ejected onto an exit conveyor.

The C-40 stick printer can be supplied to run at speeds of around 1800 to 2000 parts per minute for paper sticks, or at slightly lower operating speeds for plastic sticks where pre-treat and drying operations require longer handling times.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

C-50 Tube & Cup Printers

C-50 Tube & Cup Printers

Apex C-50 series printers are highly adaptable to suit a wide variety of specialist printing and decorating applications.

The flexible design characteristics enable the machines to have considerable scope for size adjustments to allow a variety of products to be printed. The C-50 can be supplied with a variety of print technologies ranging from dry offset and gravure, to hot foil applications or specialist coatings.

The C-50 can be supplied with a variety of print technologies ranging from dry offset and gravure, to hot foil applications or specialist coatings.

The C-50 utilizes mandrels to support flexible or rigid parts to allow printing on their full length, and 360° around. Parts commonly printed on the C-50 include:

• Barrels • Bottles • Cartridges • Containers • Cups • Syringes • Tubes • Caps

Be it a disposable syringe, a marker pen barrel, or a squeeze tube, the C-50 is one of the most flexible and versatile decoration systems on the market today.

The heart of the machine is a 6, 12, or 16 station servo driven index table with quick change horizontal or vertical mandrels mounted at centers around the machine.

Interfaced within are the appropriate:

Feeder / Loader

The feeding of components to the print system can be simple or sophisticated depending upon the type of product to be handled, and the production speed required. Typically hoppers and bowl feeds are utilized for smaller components, and inline conveyors or chutes for larger products.

Pre-Treaters

Gas treaters or corona discharge units are commonly used to pretreat plastic components to allow the highest quality of print and adhesion. Either system can be integrated within the C-50, and both are available in many different formats and types to suit every customer's unique requirements.

Decoration Unit

Any decoration technology can be integrated into the C-50. For multi-color applications, we suggest a dry offset print station. This can be supplied in different widths and with up to six color heads. For single color or overcoating applications we suggest the use of rotary silkscreening, rotary hot stamping, letterflex, or flexographic printing, with each type specifically designed and interfaced to suit your own specific requirements.

Dryers

Forced hot air, infrared, convection and ultra-violet curing units can be supplied to cure the appropriate ink for each customer's individual demands and requirements.

As with all Apex machines, we tailor each one to suit the individual customer's specification.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.