Apex Machine Company engineers and manufactures a wide range of specialist three dimensional product handling and printing machines. Each machine will typically consists of a transport system to capture and move the parts through the various processes which may include cleaning and/or pre-treating, printing, coating, curing/drying, validating, sub-assembling, packing, etc. Each of our standard transport and printing systems are available in several sizes and in different configurations, as well as with choices of different printing technologies, to suit particular decoration requirements, product sizes and types. All systems are then individually customized to precisely meet customer's specific requirements.

Apex make a wide variety of machine classes, each of which provide a whole range of customizable features to suit a huge variety of product sizes, materials and types. Printing and parts handling systems from Apex will typically include additional front end equipment such as bulk bins, elevators, bowl feeds or other handling as required to automate product flow into the printing machine. Similarly we offer a variety of solutions for in-line sub-assembly, vision analysis and verification, ejecting, rejecting, counting, bagging, boxing or handover to suit other downstream requirements.

Machines by Industry/Product type

The machines featured in this section are necessarily just a small representation from the basic types produced by Apex - please remember we custom design, engineer and build each machine to suit our customer's special applications and production requirements.

Automotive Industry Products

Automotive Industry Products- Beverage Products

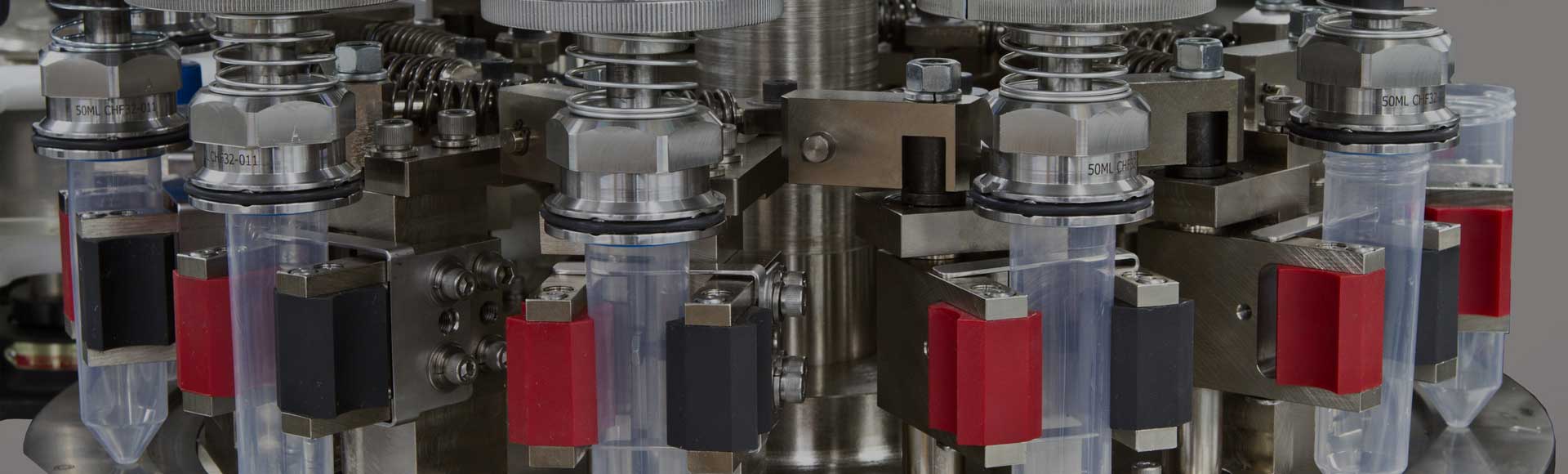

- Medical Syringe Printers

- Medical Vial &Tube Printers

- Other Medical Products Printers

- Cork Printers

- Cap and Closure Printers

- Cup, Can, Aerosol and Tube Printers

- Hardware and General Products Printers

- Extrusion and Strap Printers

- Pen, Pencil, Marker & Stationery Printers

- Food Packaging & Stick Printers

- Sports & Household Products Printers