Apex has been providing printers into this marketplace for decades and offer machines for every type of decoration requirement onto all types of pens, pencils, markers, ballpen refills, rulers, protractors, set squares, erasers, plastic clips, and more.

Apex has been providing printers into this marketplace for decades and offer machines for every type of decoration requirement onto all types of pens, pencils, markers, ballpen refills, rulers, protractors, set squares, erasers, plastic clips, and more.

Our printing solutions for this marketplace range from low speed, highly flexible, bench top units for small run advertising novelty use to high speed dedicated lines for marker pen barrels running at speeds up to 600 parts per minute.

Machine types for this market include:

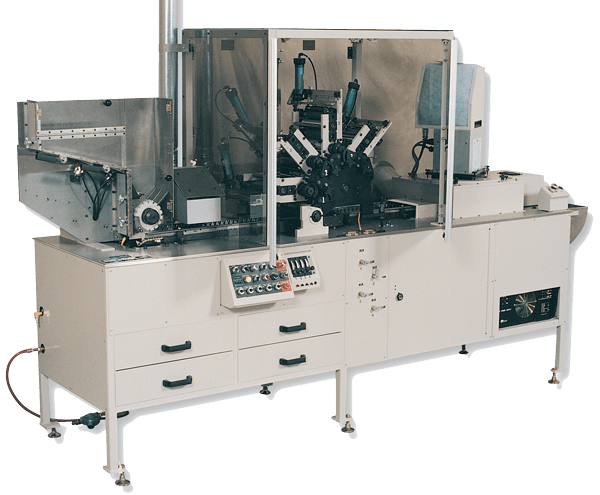

C-40 Cylindrical Parts Printers

C-40 Cylindrical Parts Printers

Apex C-40 series printers are highly adaptable to suit a wide variety of specialist printing and decorating applications. The flexible design characteristics enable the machines to have considerable scope for size adjustments to allow a variety of products to be printed. The C-40 can be supplied with a variety of print technologies ranging from dry offset and gravure, to hot foil applications or specialist coatings.

Diverse applications for the C-40 range include:

Diverse applications for the C-40 range include:

Lipstick Tubes, Golf Balls, Cans, Rigid Tubes, Corks, Cups, Bottles, Squeeze Tubes, Pill Jars and Glue Sticks to name just a few.

The C-40 can be supplied as a complete semi-automatic straight wall cylindrical part printing system that includes a feed station, pre-treat station, print station, UV drying station, and optional eject station all in one small footprint.

This machine is designed so that parts can be manually loaded onto mandrels located on a four or eight station rotary index wheel. On a four mandrel index wheel, the load mandrel is also the exit mandrel. An optional automatic eject can be added to the eight mandrel system. The C-40 can also be supplied with part or full automation for higher speed operation.

Following the loading section is an optional Gas Flame or Corona pre-treatment section where the part is rotated and the circumference is pre-treated prior to its entrance into the print station. Following the pre-treatment is the print section, where colors and graphics are added to the part. Next, the part indexes into a UV curing section where the part is rotated and the circumference is exposed to the UV light source until the ink is "cured" and dry. Finally, the part indexes so that it can be ejected.

Either a mechanical part holder or an optional Vacuum Assist mechanism is typically utilized to secure the part to a mandrel. An optional Rotational Orientation Device can be integrated on each mandrel to register the imprint on the part.

For multiple color capacity, this machine utilizes either Dry Offset or FlexApex printing methods for decorating the cylindrical objects. Each Dry Offset Print Head includes a 360° plate drum allowing for the use of Photopolymer Print Plates. These plates may be secured using a variety of optional plate mounting systems, for example, Vacuum, Magnetic, Strap-On or Double Sided Tape.

The print station can consist of up to Four Dry Offset Heads printing circumferentially on the part. If the part incorporates STRAIGHT WALLS, a 360° artwork wrap can be achieved. An optional angling device can allow for tapered parts to be printed however, the more the taper, the less artwork wrap can be achieved. In either case, spot artwork can be printed around the circumference.

The C-40 in manual loading mode operates at about 20 to 35 parts per minute, limited only by the speed of the operator. It is ideally suited for a wide variety of cylindrical products including cups and tubes. In automatic loading configurations higher operation speeds of up to 100 parts per minute can be achieved.

The following is a listing of standard options:

- Four or Eight Station layout

- Orientation Device

- Vacuum Part Assist

- Mechanical Part Assist

- Gas Flame Treating Station - for 3", 6" or 9" wide print area

- Corona Treating Station - for 3", 6" or 9" wide print area

- Up to Four Dry Offset Print Heads - for 3", 6" or 9" wide print area

- Vacuum, Magnetic, Strap-on or Double-sided Tape plate mount systems

- Ultraviolet Light Drying System - for 3", 6" or 9" wide print area

- Air Blow Off or Mechanical Eject System

- Choice of Printing Systems - Dry Offset, Flexapex, Hot Foil

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

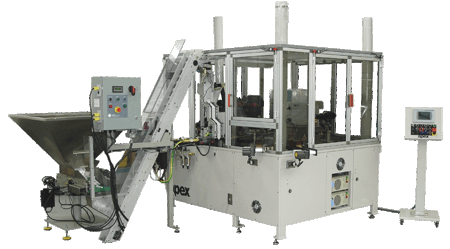

C-400 Pen & Pencil Printers

C-400 Cylindrical Parts Printers

Apex C-400 series printers are highly adaptable to suit a wide variety of specialist printing and decorating applications. They are designed to handle rigid and semi-rigid cylindrical parts which are able to withstand the pressure of the the printing process without deforming. C-400's are produced to handle parts as diverse as golf tees, pencils, aerosol cans, marker barrels, shotgun cartridges and many more. The heart of the system is a continuous motion or indexing chain assembly that carries rigid components throughout the system. Appropriate feeders, pre-treaters, cleaning systems, decoration/printing units, dryers, coaters and unloaders can all be incorporated into the system.

The heart of the system is a continuous motion or indexing chain assembly that carries rigid components throughout the system. Appropriate feeders, pre-treaters, cleaning systems, decoration/printing units, dryers, coaters and unloaders can all be incorporated into the system.

Optional automation to assist with component assembly can also be integrated.

Every customer has a different requirement and each C-400 is therefore tailored specifically to meet your needs and budget.

Features

Automation

Hopper; Chute; Vibratory Bowl; Rotary Bowl; Conveyor; In-Line

Pretreat

Gas/Flame; Corona Discharge

Cleaners

Vacuum; Air Jet; De-ionized Air; Tacky Roll; Brush

Decoration

Dry Offset; Flexapex; Rotary Silk Screen; Rotary Hot Stamp; Rotary Gravure; Letterflex; Flexographic

Drying

Air Dry; Heat Gun; Hot Air Oven; Convection Oven; Ultra-Violet

Options

Overcoat / UV Dry; Auto Cap Insert; Auto Sub-Assembly;

Vision Inspection; Auto Adjust

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

C-500 Cylindrical Tube Printers

C-500 Printers

The C-500 utilizes mandrels to support flexible or rigid parts to allow printing on their full length, and 360 degrees around.

Parts commonly printed on the C-500 include:

• Barrels • Bottles • Cartridges • Containers • Cups • Syringes • Tubes • Oil Filters

Be it a disposable syringe, a marker pen barrel, or a squeeze tube, the C-500 is one of the most flexible and versatile decoration systems on the market today.

The heart of the machine is a 6, 12, or 16 station servo driven index table with quick change horizontal or vertical mandrels mounted at centers around the machine.

Interfaced within are the appropriate:

Feeder / Loader

The feeding of components to the print system can be simple or sophisticated depending upon the type of product to be handled, and the production speed required. Typically hoppers and bowl feeds are utilized for smaller components, and inline conveyors or chutes for larger products.

Pre-Treaters

Gas treaters or corona discharge units are commonly used to pretreat plastic components to allow the highest quality of print and adhesion. Either system can be integrated within the C-500, and both are available in many different formats and types to suit every customer's unique requirements.

Machine Types

| C-500-3 | |||

|---|---|---|---|

| Part Diameter | min | 0.175" | 4.45mm |

| max | 6.00" | 152.4mm | |

| Part Length | min | 0.25" | 6.35mm |

| max | 6.00" | 152.4mm | |

| Copy Length | max | 3.00" | 76.2mm |

| C-500-6 | |||

| Part Diameter | min | 0.175" | 4.45mm |

| max | 6.00" | 152.4mm | |

| Part Length | min | 0.25" | 6.35mm |

| max | 10.00" | 254mm | |

| Copy Length | max | 6.00" | 152.4mm |

| C-500-9 | |||

| Part Diameter | min | 0.175" | 4.45mm |

| max | 6.00" | 152.4mm | |

| Part Length | min | 0.25" | 6.35mm |

| max | 10.00" | 254mm | |

| Copy Length | max | 9.00" | 226.6mm |

Decoration Unit

Any decoration technology can be integrated into the C-500. For multi-color applications, we suggest a dry offset print station. This can be supplied in different widths and with up to six color heads. For single color or overcoating applications we suggest the use of rotary silkscreening, rotary hot stamping, letterflex, or flexographic printing, with each type specifically designed and interfaced to suit your own specific requirements.

Dryers

Forced hot air, infrared, convection and ultra-violet curing units can be supplied to cure the appropriate ink for each customer's individual demands and requirements.

As with all Apex machines, we tailor each one to suit the individual customer's specification and requirements.

Technical

Up to 12" of copy can be printed on parts no more than 12" (304mm) in length and 6" (152mm) diameter. Production speed up to 200 parts per minute.

Electrical: 220, 380, 440 volt, single or 3-phase - 50/60 Hertz.

Pneumatics: 70-80 psi - 5 cfm.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

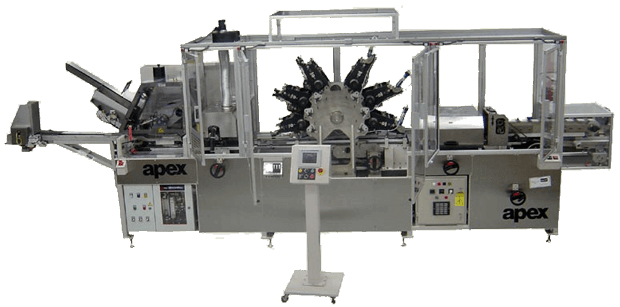

Marker Barrel Printers

C-900 Tubular Product Printers

The C-900 is a versatile machine for circumferential printing, decorating and coating of hollow tubular shaped plastic products of up to 3" diameter and 6" length. This high speed machine base is ideally suited for high volume production parts across a wide spectrum of vials, tubes, syringes, pen and marker barrels, etc.

The C-900 is a versatile machine for circumferential printing, decorating and coating of hollow tubular shaped plastic products of up to 3" diameter and 6" length. This high speed machine base is ideally suited for high volume production parts across a wide spectrum of vials, tubes, syringes, pen and marker barrels, etc.

The system automatically feeds, pre-treats, and prints 360° around the product circumference in up to four colors with UV drying. A clear coat station can also be provided.

The C-900 can be adapted to suit a range of product sizes and therefore has applications for many products. The C-900 can additionally be interfaced with appropriate pre and post print handling equipment to meet many assembly and automation requirements.

Depending upon product size and shape, production speeds of 350 - 600 parts per minute are achievable.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.

S-40 Flat Parts Printers

S-40 Multi-Purpose Flat Product Printers

S-40 printing machines from Apex offer a wide range of options for the printing of flat surface products of all types. Any of the print technologies and methods can be incorporated into these machines which are used to print a hugely diverse range of products. The S-series machines can be engineered to handle:

- rigid self-supporting parts such as blocks, solid molded or heavy-walled products

- flexible products such as ice cream carton lids, lunch meat packs, etc., requiring support for printing

- odd shaped products which have one or more flat planes for printing, including items like cosmetic products boxes and containers, plastic paper clips, hanger clips, lids, pre-made boxes for label and details overprinting.

- products requiring printing on more than one plane like egg boxes

- sawblades, lids, cap tops, rulers, single dosage packs and many more.

All systems can be supplied with the appropriate print technologies, handling and treatment options as required. Production speeds are generally over 100 parts per minute - product size is unlimited.

Detailed machine information, specifications and, in many cases, videos are available on request once we have the basic details of your application and requirements to enable us to select and supply the most relevant information and recommendations. Please click below to submit a request for additional information. We will be very pleased to provide you further information and assistance.