Printing, Marking, and Decorating of Plastics

No one would deny the tremendous growth of plastics in our world. Products, once made from other materials, are now commonly made from plastic. In many instances, the decorating and/or printing of these items contributes greatly to their initial, as well as, continued success.

Printing, marking, and decorating can be accomplished as an integral part of the molding or extruding of the plastic material or can be accomplished in additional operations. Economics and overall product goals often play a large factor in this determination. Products often go through many different printing, marking, and decorating processes in order to accomplish the intended result. Decorating techniques, such as coloring, texturizing, embossing, shaping, are readily accomplished as an integral part of the molding operation. In most cases, permanency of the printing, marking, and decorating deserves serious consideration, which often, based upon the degree of permanency, will determine the techniques utilized to accomplish this desired end result.

This discussion is limited to techniques that actually apply ink in a printed, marked, or decorative format to a plastic substrate. Other techniques that utilize materials that have been pre-printed, pre-marked, or pre-decorated are not included. Therefore, decal, hot transfer processing, labeling, name plating, shrink wrapping, in-mold insertion, laminating, co-extrusion, sublimation, wrapping, and the like are excluded. In similar fashion, discussions of air brushing, dry ink transfer, painting by mask and spray, coating, ribbon printing, flocking, spray painting, plating, stenciling, hand painting, water dispersion decorating, laser marking, dipping, metalizing, and other methods are also not included. The exclusions in no way imply that these techniques are not viable or that they are any less important than those that are included.

The following sixteen (16) basic methods all fall into the general category of printing, marking, or decorating: letterpress, letterflex, flexography, dry offset, offset lithography, rotogravure, rotogravure offset, pad, digital, digital offset, screen, inkjet, laser, heat transfer, hot stamping, labeling (inmold or sleeves). The first 13 techniques involve the utilization of wet ink; heat transfer, hot stamping, and labels are a dry method.

All of the wet ink methods require some technique to dry the ink. In most cases, the plastic substrate does not offer, as paper does, the ability to quickly absorb the ink. Solvent-based inks use methods that encourage the solvents out of the ink leaving the dry ink on the plastic. Heat, created by various methods, is often combined with air movement to accomplish this goal. Ultraviolet curing inks, which are normally solvent-free, use certain ultraviolet wave lengths to render themselves dry almost instantly. The fact that ultraviolet inks have no solvents permits them to remain wet for great periods of time taking away from the wet printing, marking, and decorating process, two major problems: environmental and ink solvent balance. Ultraviolet inks are now available for many of the processes.

Letterpress

No doubt letterpress is the oldest production printing technique. This system utilizes a backward-reading rigid printing plate with a raised image that has been inked by paste ink. The plate transfers its copy onto the product. Systems are available in flat bed, utilizing flat rigid plates, and rotary, utilizing curved rigid plates.

Letterpress printing is limited to a single color per pass. Multi-colors are accomplished by multi-processing or by presses with printing members mounted in tandem.

Letterflex

The letterflex process is an outgrowth of letterpress. The principles and applications are similar. The basic difference is that a backward-reading rubber or flexible photopolymer printing plate, rather than a rigid printing plate, is inked by paste ink which places the copy onto the product. The flexibility of the printing plate and the ability to back the printing plate with cushioning materials allows letterflex printing to imprint slightly irregular surfaces. As with letterpress, letterflex is limited to one color per pass and is available in flat bed as well as rotary techniques.

Flexography

Flexographic printing makes use of similar flexible printing plates as letterflex but differs from letterpress and letterflex in that it utilizes liquid ink. The printing plate most typically is backward reading, thus, imparting a correct reading impression to the plastic part. Often in the imprinting of film, however, a correct reading printing plate is used to print on the backside of clear film which, thus, reads correctly from the viewing side. Flexographic printing is most often utilized as a rotary method and is limited to a single color per pass. Multi-color systems are created by mounting color stations around a common drum or mounting them in tandem.

Dry Offset

A rigid correct reading printing plate with a raised image is the heart of the dry offset method. The ink is paste. The image is transferred to a smooth piece of a elastomer material known as a blanket, which accepts the ink from the printing plate and transfers the copy to the part. Dry offset printing is available in both flat bed and rotary methods. While a single color can be printed, the offset blanket, however, can in tandem engage a series of print heads, each of which applies a separate color to the blanket. The complete multi-color design, which has been superimposed on the blanket, is then transferred to the plastic part in a single pass. The printing plates are most commonly designed to have the colors dropped out of each other. Recently, with the advancement of variable tact levels inks, overprinting, wet-on-wet/multi-color printing can be accomplished in a single pass. The terms reverse letterpress or letterset are sometimes utilized to identify the dry offset process.

Offset Lithography (Wet Offset)

Closely akin to dry offset, this process is based upon the principal that oil and water do not mix. The impression is neither raised nor depressed but is planographic, flush on the correct reading printing plate. The area to be printed is receptive to ink; the area not to be printed repels it. A combination of ink rollers and wetting rollers work in conjunction, thus allowing only the area that is to be printed to receive the ink. The inked area transfers the impression to a blanket which transfers the copy to the substrate. Recent work with an old process known driography has emerged as waterless lithography, which is similar in nature to offset lithography with the exception that the system utilizes no water. A planographic silicone layered printing plate, replaces the dampening system. Specially compounded inks are combined with a press that has a precise ink temperature control system. Some work has also been done to use this type of printing plate in the dry offset process.

Gravure

Gravure printing differs from the other methods described above in that the image to be printed is depressed. Liquid ink is flowed into the backward reading etching. A knife-like device, known as a doctor blade, removes all of the ink except that which is in the depression from which the ink is transferred to the substrate.

Rotogravure

In most web plastic printing applications gravure printing is limited to a rotary process known as rotogravure. Here too, printing is limited to a single color per pass. Multi-colors are accomplished by imprinting in tandem or around a common impression cylinder.

Two other processes have grown from gravure: rotogravure offset and flat bed gravure offset commonly known as pad printing.

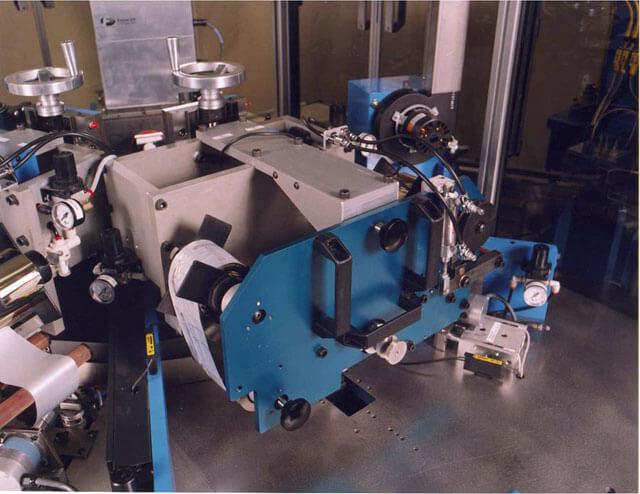

Gravure Offset (Tampo Style Pad Printing)

In this method, the image to be printed is depressed in a flat format. A doctor blade meters the flooded ink from the surface of the correct-reading flat plate allowing the pad, which in most instances is made from a soft silicone material, to accept the ink from the valley. Using a reciprocating motion, the ink is transferred to the part by the pad. Because of the flexible, low durometer nature of the pad, products of unusual shapes and wide tolerances are often able to be printed quite easily.

In this method, the image to be printed is depressed in a flat format. A doctor blade meters the flooded ink from the surface of the correct-reading flat plate allowing the pad, which in most instances is made from a soft silicone material, to accept the ink from the valley. Using a reciprocating motion, the ink is transferred to the part by the pad. Because of the flexible, low durometer nature of the pad, products of unusual shapes and wide tolerances are often able to be printed quite easily.

Hereto, as is with all methods but dry offset, multi-colors are printed by tandem operations. As with its relatives, rotogravure and rotogravure offset, pad printing typically utilizes high solvent-based inks which allows for multi-colors and over printing to be accomplished with relatively short drying distances between the tandem colors.

Rotogravure Offset

Rotogravure offset printing is similar to dry offset printing and offset lithography in the respect that a blanket is utilized. The ink from the correct-reading, doctored, depressed area is transferred to a specially compounded elastomer material, normally silicone, which transfers the impression to the plastic substrate.

As the name implies, rotogravure offset is limited to a rotary process. Multi-colors are normally achieved through the use of tandem stations.

Flexapex Process

This process, like dry offset, utilizes a blanket. The ink from the rigid, correct reading printing plate with a raised image, is transferred to a smooth piece of elastomer material known as a blanket, which accepts the ink from the printing plate and transfers the copy to the part. The main difference, when compared to dry offset, is that the process uses a combination of technologies and liquid inks, metered through anilox rolls to suit the inking density requirements of specific artworks. This process allows printing of heavier, more dense, solids than can be achieved with conventional offset inking systems, providing an ink lay down that is more comparable with silk screening or rotary gravure printing. The process is solvent (VOC) free, which is an important factor in many plants today.

Screen (Silk Screening)

Screen (Silk Screening)

In screen processing, all but the image to be printed is opaque on the printing plate called a screen which is a tightly drawn fabric originally made from silk but now available in a wide range of materials including stainless steel. The ink is placed onto the opaque area of the screen; the printing mechanism is a squeegee, generally a semi-flexible elastomer material, which wipes the ink across the screen forcing it through the open area onto the plastic product. The screen process is limited to a single color per pass and is available both in flat and rotary techniques. Multi-colors are accomplished by repeat passes or tandem processing.

Digital Offset

Digital offset is the technique of printing in which no films or printing plates are utilized. The images are formed through the utilization of diskettes or desk top processing allowing direct on-press printing. As the word offset implies, there is a blanket to which the color is applied. In some cases of multi-color work, each color is applied sequentially with rotation of the blanket drum. All colors are then, through a final rotation of the blanket drum, transferred simultaneously to the substrate. The nature of the process is such that following each blanket transfer to the substrate, the blanket may receive a new image which may be totally different from the one just printed. In essence, with each print 100 percent of the blanket's image is transferred to the substrate. The systems are normally provided in the rotary technique.

Ink Jet

This method is non-contact. As such, there is no physical engagement of the plastic substrate and the printing or marking device. The principles of jet printing are based upon the fact that ink under heavy pressure can be forced through a nozzle and without product contact form dot matrix patterns. The systems are essentially either drop on demand or continuous dropping units allowing for computer controlled signalling to determine the opening and closing of valves as needed to create the required image. Multiple jets can be utilized to create the desired or multi-color end results. Production inkjet systems are available in flat bed applications.

Laser

This method is non-contact. As such, there is no physical engagement of the plastic substrate and the printing or marking device. The principles of laser printing are based upon the fact that a laser (typically of CO2 or YAG) can be directed with an XY or XYZ axis movement to a part in a matrix fashion that leaves a graphic burned into the surface. The graphics quality is typically dependent upon the accuracy of the motion moving the laser head (or sometimes the part) combined with power and the diameter of the laser beam. This cannot provide multiple color results. Production laser systems are available in flat bed applications.

Heat Transfer (and/or Dye Sublimation)

All of the previous techniques utilize a wet ink material to transfer the print, mark, or decoration to the substrate. Heat Transfer stamping typically utilizes a solid silicone plate or roll with a pre-printed film that looks like a roll of decals. In some applications, a flexible plate is employed. Artwork is pre-printed printed onto a specialized heat sensitive film utilizing another printing process (like Screening, Flexography, Gravure, or Digital). This film is essentially dry color laminated with a release coat and an adhesive coat to a carrying mechanism such as mylar in a roll format. For each impression, a special locating “eye” has been printed at exact equal spacing over the film. The film is fed through a web and delivered by the heat transfer system in relationship to the heated silicone, where through heat, dwell time, and pressure, the printing of the desired image is released to the plastic material. Heat transfer systems are available in flat bed as well as rotary versions.

Hot Stamping

Hot stamping is very similar to Heat Transfer. While, all of the previous techniques utilize a wet ink material to transfer the print, mark, or decoration to the substrate, hot stamping utilizes a dry foil and heat. Hot Stamping typically utilizes a relieved, backward reading rigid metal plate. In some applications, a flexible plate is employed.

Hot stamping is very similar to Heat Transfer. While, all of the previous techniques utilize a wet ink material to transfer the print, mark, or decoration to the substrate, hot stamping utilizes a dry foil and heat. Hot Stamping typically utilizes a relieved, backward reading rigid metal plate. In some applications, a flexible plate is employed.

Color is provided by foil, which is essentially dry color laminated with a release coat and an adhesive coat to a carrying mechanism such as mylar in a roll format. For each impression, a clean section of foil is delivered by the hot stamping system in relationship to a heated die which through heat and pressure releases the color in the desired image to the plastic material.

Hot stamping systems are available in flat bed as well as rotary versions. Multi-colors are accomplished by multi-passes or tandem operations. This process provides the best Metallic finish decoration.

Labeling (Inmold and Sleeve)

Labeling is similar to heat transfer and hot stamping. It is a dry process where a roll of pre-printed artwork is applied to the part. Like Heat transfer and Hot Stamp, it is a dry process. While heat transfer utilizes heat to transfer artwork from a film, a labeling system winds the roll so that an adhesive-backed individual label can be peeled off and transferred to a part. Sometimes this application involves a roller to press-on the label, and other times it involves a blower to apply the label. With inmold, a label is strategically applied into the mold of an injection mold system so that it is bonded as part of the molding process. With sleeving, the pre-printed label is in the form of a tube that typically uses gravity to float the tube over a part so that it can be heated to cause a shrinking and bonding action around the part. This process is good for difficult geometries and little structural support. This is a single pass technique where all graphics are pre-printed.